CAP Screening automation continues to be adopted across the Nuclear industry. As of April 2022, at least 4 nuclear utilities in North America have implemented or are currently implementing CAP Screening automation, and at least a half dozen more are strongly considering pursuing it in the near future. However, not everyone in the nuclear industry is intimately familiar with the concept, or may only have a partial picture of the scope of CAP Screening Automation. In this post, we will quickly cover the basics of CAP Screening, automation, and the value it can deliver for utilities operating Nuclear Power Plants.

Corrective Action Programs and Nuclear Power Plants

For those unfamiliar with nuclear power operations, every Nuclear Power Plant operating within the US is required by law to run a Corrective Action Program (CAP). In the Nuclear Regulatory Commissions own words, CAP is:

The system by which a utility finds and fixes problems at the nuclear plant. It includes a process for evaluating the safety significance of the problems, setting priorities in correcting the problems, and tracking them until they have been corrected.

https://www.nrc.gov/reading-rm/basic-ref/glossary/corrective-action-program.html

CAP is an integral part of operating a nuclear power plant, and touches almost every person and process inside the organization. It also happens to be a manually intensive process, and costs each utility millions of dollars in labor costs each year to run.

CAP Screening

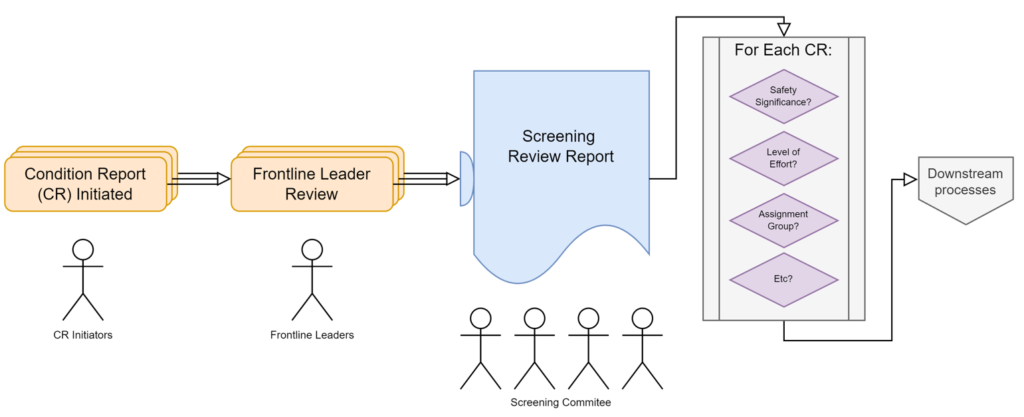

Screening incoming issue reports is the biggest process component of running a CAP, and is how utilities “…[evaluate] the safety significant of the problems [and set] priorities in correcting the problems…”. The screening process often starts immediately after a Condition Report is initiated, when a frontline leader reviews the report, verifies all appropriate information is captured, and sometimes escalates the issue to operations or maintenance. Next, the Condition Report is sent to either a centralized “screening committee”, or to distributed CAP coordinators. These groups review each and every Condition Report to evaluate safety significance, assess priority, and assign tasks. Somewhere between 5,000 and 10,000 Condition Reports per reactor are generated and go through this process each year.

In addition to the core screening, most utilities also screen Condition Reports for regulatory impacts, reportability, maintenance rule functional failure applicability, trend codes, and other impacts. These are important parts of the CAP Screening process, even if they are sometimes left out of conversations about CAP Screening automation.

Automating CAP Screening with AI

Every step in CAP Screening listed above is a manual process. The leader review, screening, and impact assessments are all performed by people. Each of the listed steps has a well defined input, well defined outputs, and has been performed more or less the same way for years. This consistency and wealth of historical data makes CAP Screening ripe for automation using artificial intelligence.

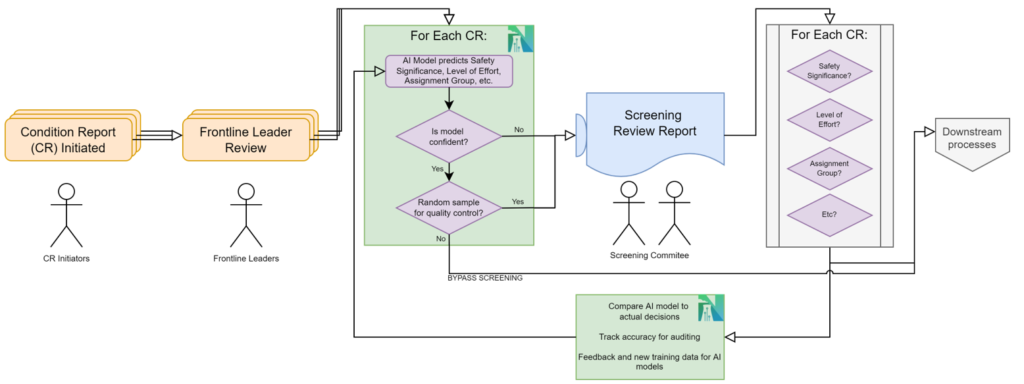

Introducing AI-driven automation into the CAP Screening process allows many of the Condition Reports to bypass the manual steps in the process. Before being screened, Condition Reports are instead sent through an AI agent trained on years of historical data that will predict the safety impacts, priorities, etc. and produce the confidence in it’s predictions. Based on system configuration, Condition Reports with the highest confidence will bypass the manual screening process altogether.

In the best implementations, CAP Screening automation will also include sending a small portion of “automatable” condition reports through the manual screening process. This “human in the loop” approach facilitates continuous quality control of the AI by comparing results from the manual process to what the AI would have done. When combined with detailed audit records, the CAP Screening automation system can produce audit reports and metrics that helps the organization ensure the quality of their CAP Screening.

Results will vary by utility, but a site adopting CAP Screening automation can expect to automate screening on anywhere between 10% to 70% of their Condition Reports. The proportion of Condition Reports automated is a function of the accuracy of the AI models, the consistency of the historical screening process, and the “risk of inaccuracy” the utility is willing to take. We expect this proportion to continue to increase in the future as AI models improve and CAP programs are adjusted to include automation.

Why are Utilities Interested in CAP Screening Automation?

Correctly implemented, CAP Screening automation is a very high value proposition for a utility. CAP Screening personnel are often highly experienced, highly paid, and in short supply. Reducing the number of Condition Reports that have to be manually screened reduces the number of personnel that have to be dedicated to CAP Screening. Automation also improves the consistency of screening and assignment, reducing rework and reassignments. Automation also eliminates the screening lead time for many Condition Reports, allowing utilities to act more quickly on the issues identified in CAP.

Various Nuclear Power Plants in North America are automating portions of the CAP Screening processes using artificial intelligence and realizing the value today. Automated screening is one of the reasons why we believe AI is the promising future of Nuclear CAP. The efficiency savings, improved consistency, reduce CAP-maintain-operate cycle times, and other benefits from CAP Screening automation are too valuable to ignore, and we expect most nuclear utilities to Capitalize on CAP Screening automation over the next several years.

Interested in automating the CAP Screening Processes at your plant? Nuclearn offers a commercial CAP Screening Automation software solution leveraging state of the art AI models tailored to nuclear power. Learn more by setting up a call or emailing us at sales@nuclearn.ai